The medical industry is undergoing a profound transformation, driven by rapid advancements in technology and evolving expectations for patient care. Among the most significant yet often overlooked innovations are the sophisticated coatings being developed for medical devices. These coatings have become indispensable in improving performance, enhancing safety, and supporting the long-term durability of critical tools used in everything from diagnostics to complex surgical procedures.

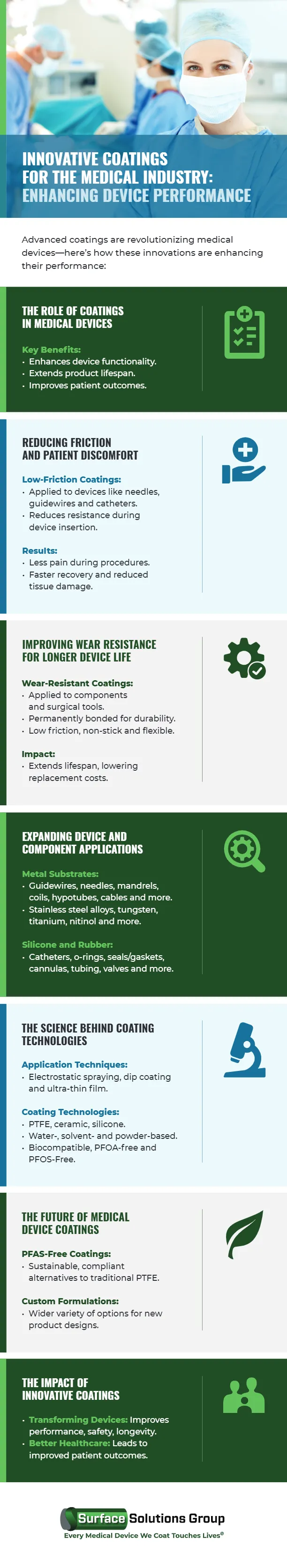

Modern coatings are designed to perform much more than basic protection. They serve as integral performance enhancers, especially in devices that make direct contact with bodily tissues or fluids. A standout benefit is the ability of these coatings to reduce friction — an essential factor for tools like catheters, guidewires, and surgical needles. Devices with hydrophobic or lubricious coatings can glide effortlessly through soft tissues, reducing the risk of tissue trauma, increasing procedural accuracy, and minimizing patient discomfort.

The medical environment demands not only functionality but also resilience. Devices used in invasive or high-frequency applications must endure harsh conditions, including sterilization cycles and exposure to fluids and chemicals. That’s where coatings like PTFE come in. Known for its exceptional resistance to heat, moisture, and corrosion, PTFE enables devices to perform consistently under extreme conditions. Its non-stick surface also helps prevent biofilm formation, lowering the risk of contamination and infection.

One of the most promising trends is the expansion of coating applications across a variety of device types and materials. Coatings are now tailored to enhance performance on metal substrates such as stainless steel, nitinol, tungsten, and titanium, as well as elastomeric and polymer-based materials like silicone and rubber. Devices that rely on flexibility and sealing, such as cannulas, tubing, and o-rings, gain both strength and efficiency from these advanced surface treatments.

Moreover, as medical devices become more complex and multifunctional, coatings are adapting to meet increasingly specialized demands. Electrical insulation, chemical resistance, and even drug-eluting capabilities are being built into coating systems, opening the door for smarter, more adaptive medical tools.

The benefits are far-reaching. Healthcare providers gain tools that are more reliable and easier to use. Patients experience fewer complications and more comfortable procedures. And manufacturers gain the ability to differentiate their products through higher performance and longer device lifespans.

The evolution of medical coating technologies is fundamentally reshaping the landscape of healthcare. These innovations are ensuring that medical devices not only keep pace with clinical demands but also proactively address the needs of both patients and medical professionals. As we look toward a future of increasingly personalized medicine, the strategic use of coatings will continue to play a pivotal role in achieving safer, smarter, and more effective medical care.